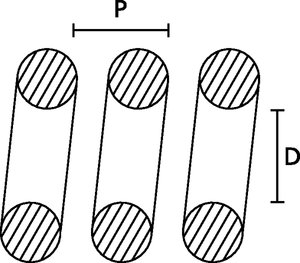

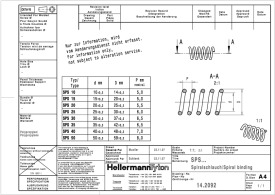

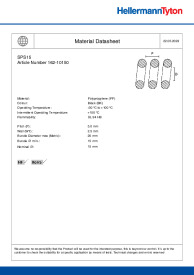

Spiral binding 15 mm - 20 mm, PP, black, 1 m

Art.-No. 162-10150

| SPS15-PP-BK

|

Details

- Heavy-walled and very robust

- Excellent protection from mechanical stress

- Very high abrasion resistance

- Very good resistance to oils

- Available in diameters up to 50 mm

- Ideal for larger cable bundles

Request your individual offer now

Request quote

More products in this product group:

| Application | SPS spiral binding is especially suitable for the use in areas where high abrasion resistance and much larger cable diameters are needed, for example the automobile and petrochemical industry as well as in heavy plant construction. |

| Colour | Black (BK) |

| Local order number | SPS15 |

| Material | Polypropylene (PP) |

| Pack Cont. | 1pc. |

| Package Content packed in | pcs. |

| PART DESCRIPTION | SPS15-PP-BK |

| Product Family | SPS |

| Product Group | Polypropylene spiral binding for high resistance against oil, narrow pitch |

| Short Description | Spiral binding 15 mm - 20 mm, PP, black, 1 m |

| Variant | Spiral Binding |

| Country of Origin | DK |

| Customs Number | 39269097 |

| GTIN-13 / EAN | 4031026124001 |

| Packaging 3 - Height (m) | 0.4m |

| Packaging 3 - Length (m) | 1.01m |

| Packaging 3 - Qty | 250 |

| Packaging 3 - Type | Carton |

| Packaging 3 - Volume (m³) | 0.1394m³ |

| Packaging 3 - Weight (kg) | 22.315kg |

| Packaging 3 - Width (m) | 0.345m |

| Packaging 4 - Height (m) | 0.945m |

| Packaging 4 - Length (m) | 1.2m |

| Packaging 4 - Qty | 1000 |

| Packaging 4 - Type | pallet |

| Packaging 4 - Volume (m³) | 0.907m³ |

| Packaging 4 - Weight (kg) | 110.259kg |

| Packaging 4 - Width (m) | 0.8m |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Turkey

Turkey United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

Download

Download

SPS10

162-10100

SPS10

162-10100