Heat shrink marker, thermal transfer print, continuous, 19.0mm/9.5mm, white, 26m

Art.-No. 551-41006

| THTT190WH-PVDFX-WH

|

Copied

This product is not available anymore.

Alternative product available

- Shrink ratio 2:1

- PVDFX high temperature tube

- Thermal transfer or laser beam printable

- Available in white and black as standard

- Good mechanical strength and highly flexible

- Delivery in convenient storage boxes

Request your individual offer now

Request quote

More products in this product group:

| Application |

THTT is a 2:1 high temperature, flame retardant heat shrink marker supplied in continuous tube and on convenient reels that allows printing on both sides if required. The printed marker is ideal for use in applications where high temperature and exposure to aggressive solutions are found. The tubing has been especially prepared so that the print performance is excellent at all times using HellermannTyton's printer range. A standard heat gun with reflector is used to shrink the sleeves onto the wire or cable to achieve a permanent mark. In addition it is possible to either perforate the tubing at pre-determined lengths or fully sever the markers. The material is also especially formulated to be printable with laser beam printers. |

| Behaviour at low Temperature test method | ASTM D2671 |

| Colour | White (WH) |

| Fixation Method | Suspend |

| Heat Aging Test | 168h/225°C |

| Heat Aging test method | ASTM D638 |

| Heat Shock Test | 4h/275°C |

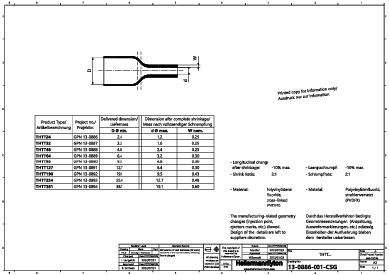

| Material | Polyvinylidene Fluoride cross-linked (PVDFX) |

| PART DESCRIPTION | THTT190WH-PVDFX-WH |

| Package Content | 26m |

| Package Content packed in | Carton |

| Print Method | thermal transfer print |

| Print Method (Alternative) | laser beam print |

| Printable | Yes |

| Product Family | THTT – 2:1 Aerospace High Temperature |

| Product Group | Shrinkable markers "Continuous Tube", thermal transfer |

| Short Description | High temperature shrinkable markers continuous THTT 2:1 printable 19.0/9.5 white 26m/box = 2 reels |

| Shrink Ratio | 2:1 |

| Type | THTT190WH |

| Variant | Roller form |

| Weight/Unit | 1.45kg |

| With inner glue (Yes/No) | No |

| With label space | Yes |

| ELV compliant Dir. Art. 4 (2) | YES |

| Elongation at break (min.) | 300% |

| Elongation at break test method | ASTM D638 |

| Hazardous Goods | No |

| Minimum Shrink Temperature | +120 °C |

| Operating Temperature | -55 °C to +225 °C |

| ROHS compliant | Yes |

| Recommended Ribbon Type | TTRHT |

| Reel Variant | continuous |

| Specifications |

|

| Specifications | MIL-STD-202G Method 215K, SAE - AS81531 |

| Tensile Strength | 31MPa |

| Test Method Tensile Strength | ASTM D638 |

| Volume Resistance | 10¹² Ω cm |

| Volume Resistance test method | ASTM D876 |

| Water Absorption | 0.50% |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

Download

Download

TT4030

556-04037

TT4030

556-04037 TT431

556-00400

TT431

556-00400 TT4030DS

556-04061

TT4030DS

556-04061